Learning how to protect large spare parts stored indoors is critical for manufacturers and maintenance teams managing long-term inventories. Furthermore, even in indoor environments, corrosion risks remain. As a result, humidity, condensation, temperature changes, and airborne contaminants can all trigger rust and surface degradation over time.

Large components such as shafts, bearings, rotors, gears, and housings often sit idle for years. Without a structured corrosion control plan, exposed metal surfaces can deteriorate, leading to costly rework or premature replacement.

Surface preparation to protect large spare parts stored indoors

Proper surface preparation is the foundation of any long-term corrosion prevention strategy. Before storage, all parts should be thoroughly cleaned to remove machining residues, oils, salts, and fingerprints that can accelerate corrosion.

ZERUST® AxxaWash™ industrial cleaners and degreasers

are designed to remove hydrocarbon soils and contaminants without leaving corrosive residues. Afterward, parts must be completely dried. Otherwise, residual moisture trapped under coatings or packaging can compromise protection.

Furthermore, to prevent recontamination, handle cleaned parts with clean, dry gloves.

Rust preventative coatings for long-term indoor storage

Once prepared, apply a ZERUST® Axxanol™ rust preventative coating selected for the storage duration and environmental conditions.

- For short-term indoor storage up to one year in controlled environments, Axxanol™ 33 provides a light oil film that offers reliable protection and easy removal.

- For medium-term storage of one to two years, especially in areas with moderate humidity, Axxanol™ 750-NV or 758-NV delivers strong contact corrosion protection. These water-displacing oils resist oxidation and humidity exposure.

- For long-term indoor storage of two to five years or in environments with fluctuating humidity, Axxanol™ A35-8030 provides a durable oil-based barrier designed for extended protection.

Explore ZERUST® rust preventative coatings

Review the full range of ZERUST® Axxanol™ oil-based and specialty rust preventative coatings designed to protect large spare parts stored indoors under a wide range of environmental conditions and storage durations.

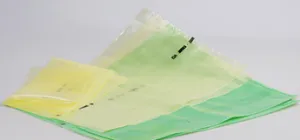

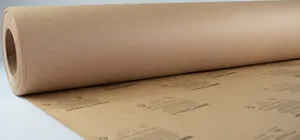

Using VCI packaging to protect large spare parts stored indoors

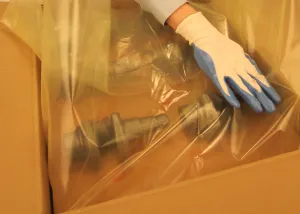

When storage extends beyond three years, coatings alone may not be sufficient. Combining a rust preventative coating with ZERUST® ICT® VCI packaging significantly increases protection life.

ZERUST® ICT® VCI films and papers emit vapor corrosion inhibitors that form an invisible molecular layer on metal surfaces. As a result, this vapor-phase protection reaches exposed areas, seams, and hard-to-coat surfaces that oils alone may miss.

For shafts and machined surfaces, apply the selected Axxanol™ coating, wrap the part in ICT® VCI paper, and fully enclose it in ICT® VCI film. Seal all seams tightly to limit air exchange and maintain a protected internal environment.

Component-specific methods for indoor spare part protection

Different components benefit from tailored protection methods.

Bearings should be coated with Axxanol™ 33, wrapped in ZERUST® ICT® VCI paper, and sealed inside ICT® VCI poly bags. As a result, this layered approach protects rolling elements, races, and internal surfaces.

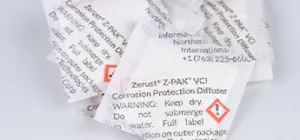

Large housings, gearboxes, or crates benefit from additional vapor corrosion inhibitor (VCI) technologies. ZERUST® Vapor Capsules, ActivPak®, or Z-PAK® VCI emitters provide continuous vapor-phase protection inside enclosed spaces.

Add vapor protection with ZERUST® VCI emitters

ZERUST® VCI emitters and diffusers release corrosion-inhibiting vapors that protect bearings, shafts, and enclosed assemblies inside crates, totes, cabinets, and housings during long-term indoor storage.

Environmental control strategies for indoor storage areas

Environmental management plays a key role in how well you protect large spare parts stored indoors. Even inside warehouses, relative humidity and temperature swings can cause condensation.

Whenever possible, maintain relative humidity below 50 percent. Furthermore, avoid storing parts near exterior doors, uninsulated walls, or areas with poor airflow.

Inside sealed packaging, crates, or totes, ZERUST® ActivDri™ PWA Packets help control moisture. These packets combine desiccant action with vapor corrosion inhibition to stabilize the internal microenvironment and reduce humidity-driven corrosion.

Inspection and maintenance during long-term indoor storage

Long-term storage is not a set-and-forget process. Inspect stored components every six to twelve months. Look for signs of condensation, coating degradation, or packaging damage.

Verify that seals remain intact and reapply coatings if necessary. Consequently, periodic inspection helps catch issues early and ensures protection remains effective throughout the storage period.

A system-based approach to protect large spare parts stored indoors

Protecting large spare parts for years requires a system, not a single product. By following this structured approach and using AxxaWash™ cleaners, Axxanol™ rust preventatives, ICT® VCI packaging, and regular environmental monitoring, ZERUST® helps manufacturers and maintenance teams ensure that critical spare parts remain clean, dry, and corrosion-free throughout their storage period. Furthermore, this process-driven methodology is central to the ZERUST® Z-CIS® (Corrosion Inhibiting System) approach, which provides consistent, long-term protection and peace of mind for industrial assets. For guidance on selecting the best solution for your needs, you can contact ZERUST®/EXCOR® to speak with a technical service representative.

Talk to a ZERUST® corrosion protection expert

Every indoor storage environment presents unique corrosion risks. ZERUST® technical specialists can help you design a system-based solution to protect large spare parts stored indoors based on part geometry, storage duration, and environmental conditions.