This test aims to demonstrate the efficiency of ZERUST® Flange Savers® anti-corrosion protection system for valves, flanges, and welded joints, to protect their physical and mechanical integrity from the corrosion effects generated by harsh environmental conditions with the presence of acid gases. The test was carried out in compliance and in accordance with the customer’s guidelines regarding “Procedures to incorporate new technologies and best maintenance practices.”

To evaluate the effectiveness of ZERUST® Flange Savers® corrosion protection on five valves. The Flange Savers® were installed on a selected site as part of a gas line pilot field test. The flange (PTP6) was located on the SVMP-1 Vertical separator because of the presence of acid vapors and its contrast with the external temperature (this area of the pipe and flange is always wet and generates moisture and presents serious corrosion problems).

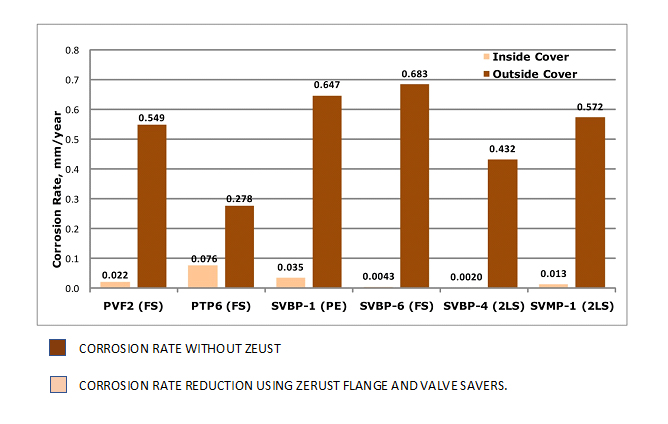

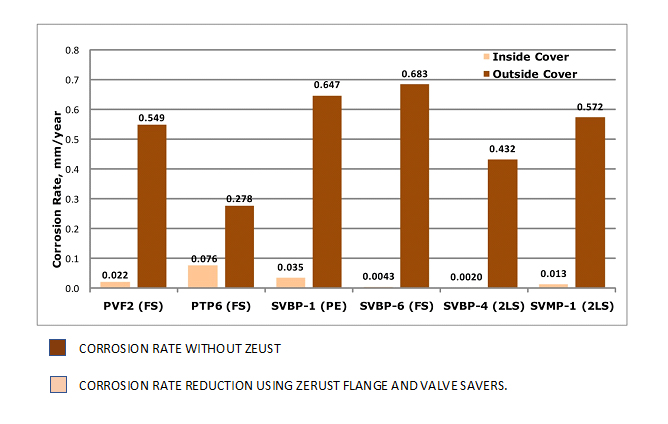

To measure the corrosion rate, we used three external and three internal metal coupons (1010 Steel) as witnesses; three were enclosed in the valve and flange body, and another series of three witnesses were left exposed outside.

At the end of the trial period (3 months), all the coupons were recovered and cleaned in our laboratory, the weights of the interior and exterior controls of each case were compared with its initial weight, and the weight difference of the coupons permits determinate the annual corrosion rate at which each valve and/or flange is exposed, and the protected witnesses showed the corrosion protection degree of that ZERUST® Flange Savers® valve protectors and flanges provide.

Test Ambient Conditions:

- Relative Humidity Range: 50% to 95%

- Temperature: 10ºC to 37ºC

- Cl and traces of H2S y SO2 are present in the environment.

TEST RESULTS: Three Months Later:

Metal Plate Analysis: Annual corrosion rate.

- With ZERUST® Protection = 170 mm/year

- Without ZERUST® = 190 mm/year

- 25 Times valve life expectancy in tough environmental conditions.