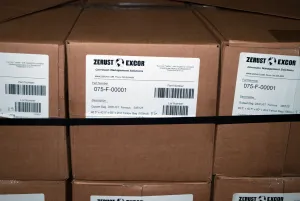

The best way to store VCI products before use is to keep them in their original, sealed packaging and store them in a clean, dry, and climate-controlled environment. Proper storage preserves the corrosion-inhibiting chemistry and ensures VCI materials perform as intended when deployed.

VCI products rely on carefully balanced formulations that release Vapor Corrosion Inhibitor Technology (VCI) only when needed. Furthermore, improper storage can allow these vapors to dissipate prematurely, reducing the effectiveness of VCI protection.

Recommended Storage Conditions for VCI Products

To maintain performance and shelf life, follow these storage guidelines:

- Store VCI products in a dry, covered warehouse

- Maintain temperatures between 0°F and 85°F (-18°C to 29°C)

- Keep relative humidity below 60%

- Avoid exposure to direct sunlight, heat sources, or standing moisture

These conditions help prevent premature activation and degradation of the corrosion-inhibiting compounds.

Why Keeping VCI Products in Original Packaging Matters

Always keep VCI products in their original packaging until use. The factory-sealed packaging is designed to protect the material from atmospheric contamination and unintended vapor release.

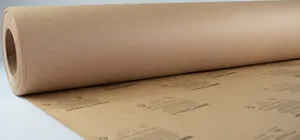

If the packaging is opened and the product is not used immediately, reclose it tightly at the end of each shift or during production downtime. This minimizes exposure to ambient air and extends usable life.

How to Store Opened or Partially Used VCI Materials

When VCI products will not be used for an extended period:

- Enclose them in airtight plastic packaging

- Remove excess air before sealing

- Clearly label partially used materials for inventory control

This approach helps preserve the corrosion inhibitors and prevents contamination from dust, moisture, or other chemicals in the warehouse environment.

Still unsure about the best way to store your VCI products?

Because storage conditions vary, our corrosion experts can help you confirm proper handling for your facility.

Common Storage Mistakes to Avoid

To ensure the best way to store VCI products before use, avoid these common errors:

- Leaving rolls or bags exposed to the open air overnight

- Storing VCI materials near acids, solvents, or corrosive chemicals

- Allowing packaging to remain open between shifts

- Storing VCI products in high-humidity or unconditioned spaces

Each of these mistakes can reduce the effectiveness of the VCI and shorten product shelf life.

How Proper Storage Extends VCI Shelf Life

When stored correctly, VCI products maintain their corrosion protection properties for extended periods. Proper storage ensures that the inhibitors remain available to protect metal surfaces during shipping, storage, and layup.

Want deeper guidance on storing VCI products?

To go further, explore proven storage best practices that help preserve VCI performance and extend shelf life.