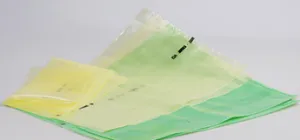

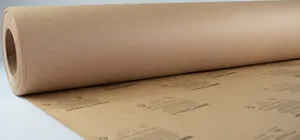

One common question is how much VCI must be placed in the packaging to ensure effective corrosion protection. Therefore, the amount of VCI required depends on how completely the packaging encloses the metal parts and on the complexity of the package geometry. To achieve effective corrosion protection, fully enclose the component or enclosed volume with an active ZERUST®/EXCOR® VCI material, such as VCI film or VCI paper.

When manufacturers completely wrap or seal parts inside ZERUST®/EXCOR® VCI packaging, the packaging creates the correct concentration of corrosion-inhibiting vapor inside the enclosure. As a result, manufacturers do not need additional VCI materials.

However, the type of merchandise, the internal package layout, and the exposure conditions determine how much VCI manufacturers must place in the packaging.

How much VCI must be placed in the packaging when using full VCI packaging?

When manufacturers use complete ZERUST®/EXCOR® VCI packaging, the packaging provides the required level of corrosion protection. Consequently, VCI molecules release from the film or paper and move throughout the enclosed space, where they form a protective molecular layer on exposed metal surfaces.

- Simple part geometries

- Single metal components

- Fully wrapped pallets, crates, or cartons

- Short to medium-term storage and shipment

Proper enclosure is critical. For this reason, gaps, loose wrapping, or unsealed openings can reduce vapor concentration and protection effectiveness.

How much VCI must be placed in the packaging for complex parts or assemblies?

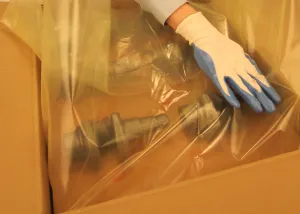

Complex parts require additional evaluation to determine how much VCI manufacturers must place in the packaging. Additionally, components with internal cavities, blind holes, recesses, or overlapping surfaces can restrict vapor circulation.

In these situations, it is advisable to supplement VCI packaging with ZERUST®/EXCOR® VCI Emitters and Diffusers. As a result, these products release additional corrosion-inhibiting vapor directly into hard-to-reach areas, helping maintain uniform protection throughout the enclosure.

Manufacturers commonly recommend additional VCI emitters for:

- Parts with deep internal cavities

- Multi-level or nested assemblies

- Multimetal components

- Large containers or crates with high internal volume

Using supplemental emitters ensures consistent vapor concentration where VCI film or paper alone may not fully reach.

How much VCI must be placed in the packaging based on package volume?

VCI protection is based on enclosed volume rather than part weight. Furthermore, larger packages contain more air space and require sufficient active VCI surface area to saturate the enclosure.

When packaging large components, pallets, or export containers, it is important to:

- Fully line or wrap the enclosure with ZERUST®/EXCOR® VCI materials

- Design the package to eliminate dead air zones and allow vapor to move freely.

- Add VCI emitters when the enclosure volume increases, or the geometry becomes complex

ZERUST® technical experts can help calculate the appropriate VCI coverage based on enclosure size, exposure conditions, and required protection duration.

Best practices for determining how much VCI must be placed in the packaging

To achieve consistent corrosion protection, follow these best practices:

- Fully enclose parts using ZERUST®/EXCOR® VCI film or paper

- Minimize air exchange by sealing packages tightly

- Add VCI emitters for difficult-to-access areas

- Increase VCI coverage for larger package volumes

- Consider environmental factors such as humidity and transit time

A system-based approach ensures the correct amount of VCI is present throughout the enclosure.

A System-Based Approach to VCI Protection

Learn how ZERUST® engineers corrosion protection systems based on enclosure volume, part geometry, and environmental exposure.

Need help determining how much VCI must be placed in the packaging?

Every application is different. Part geometry, metal type, package volume, and exposure conditions determine how much VCI manufacturers must place in the packaging.

ZERUST® corrosion experts can help you select the correct combination of VCI packaging, emitters, and supplementary protection to ensure reliable corrosion prevention during storage and shipment.

Need Help Determining How Much VCI to Use?

ZERUST® corrosion experts can help you determine the correct VCI packaging, emitters, and system configuration based on your parts, enclosure volume, and environmental conditions.