Yes, wood can cause corrosion on metal when certain environmental and chemical conditions are present. Wooden pallets, crates, and dunnage are commonly used in metal storage and transportation, but they can unintentionally accelerate corrosion if moisture, wood chemistry, or treated preservatives interact with exposed metal surfaces.

Understanding why wood causes corrosion on metal is critical for manufacturers, exporters, and maintenance teams looking to prevent rust without abandoning cost-effective wood packaging.

Why does wood cause corrosion on metal?

Wood contributes to metal corrosion through a combination of moisture retention, chemical emissions, and wood treatment compounds. These factors create an environment that promotes electrochemical corrosion.

Moisture absorption and retention

Wood naturally absorbs moisture from the surrounding environment. When wood moisture content exceeds approximately 15 to 18 percent, it can hold enough water to support electrochemical corrosion when metal parts are in contact or nearby.

High humidity, condensation, and temperature swings further increase the risk, especially during overseas shipping or long-term storage.

Copper-based wood treatments

Many industrial pallets are treated with copper-based preservatives such as ACQ or CA. These treatments release copper ions when moisture is present. Copper ions accelerate oxidation, particularly on steel and galvanized metal components.

This type of corrosion is often localized and aggressive, making it difficult to diagnose without understanding the role of treated wood.

Natural wood chemistry

Even untreated wood emits organic acids such as acetic and formic acid. These acids lower the pH around metal surfaces and increase corrosion potential. Certain wood species also contain tannins that can further influence corrosion behavior when moisture is present.

Scientific validation

Laboratory testing and field studies consistently show increased corrosion rates when wood and metal are exposed together in humid environments. Galvanized steel is especially vulnerable when in contact with treated wood under elevated humidity conditions.

Experiencing rust issues with your metal parts?

If you are seeing unexpected corrosion during storage, shipping, or palletized staging, the ZERUST® technical team can help identify the root cause and recommend a proven corrosion protection solution.

How wood-related corrosion affects metal parts

Wood-induced corrosion often appears as surface rust, staining, pitting, or premature coating failure. In severe cases, corrosion can compromise dimensional tolerances, surface finish, and overall part performance.

These issues commonly arise during storage, export shipping, and staging on wooden pallets or skids.

How to prevent corrosion caused by wood packaging

Wood-induced corrosion is a known risk, but it is highly preventable.

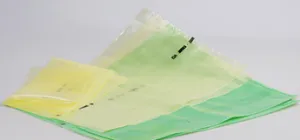

ZERUST® VCI packaging isolates metal components from corrosive elements released by wood. ZERUST® VCI films and bags create a controlled microenvironment that protects metals without requiring direct contact between wood and metal.

When properly applied, ZERUST® VCI packaging:

- Blocks moisture, organic acids, and copper ions released from wood

- Buffers humidity fluctuations inside the package

- Delivers invisible VCI protection that bonds to metal surfaces

- Protects hard-to-reach areas and complex geometries

- Allows continued use of wooden pallets for strength and cost efficiency

This approach eliminates the corrosion risk while maintaining existing logistics and packaging workflows.

Learn more about wood and pallet-related corrosion

For a deeper technical explanation and real-world examples, we encourage you to read the full blog post:

Wood and Pallets Causing Corrosion: How ZERUST® VCI Packaging Eliminates the Risk