How to Select the Right Parts Washer Fluid

Choosing the right parts washer fluid is essential to ensure effective cleaning, prevent corrosion, and protect sensitive metals during production, maintenance, or storage. ZERUST® has solutions that are aqueous-based, non-flammable, and environmentally responsible. Our solutions are engineered to meet the performance demands of spray, immersion, and ultrasonic systems. This guide outlines how to match the right parts washer fluid to your equipment type, metal substrates, and cleaning requirements.

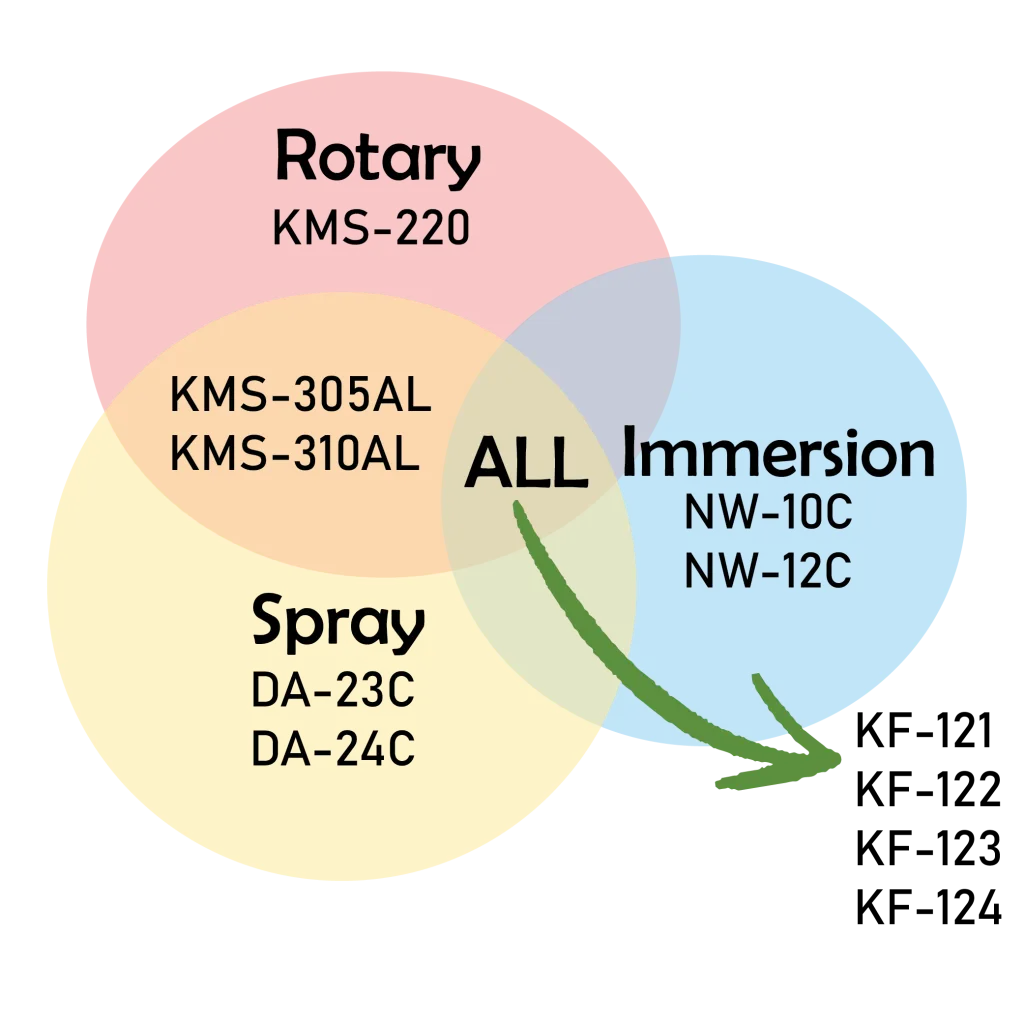

Application Method Compatibility

Aqueous parts washer fluid systems require different water-based solution fluid characteristics, especially when it comes to foam levels, rinse needs, and application method. Choosing based on machinery will help create a more efficient system.

Spray Washers:

Spray washers rely on high-pressure nozzles to clean parts, so parts washer fluids must remain low-foam to prevent interference with spray performance.

Best Choices: KF-121, KF-122, KF-123, KMS-305AL, KMS-310AL, KF-124, DA-23C, DA-24C

- KF-121 delivers consistent low-foam cleaning for medium-duty soils. It’s an ideal cleaner when a low application temperature is desired.

- KF-122 delivers consistent low-foam cleaning for heavy-duty soils and is compatible with very hard water.

- KMS-305AL and KMS-310 are designed for spray applications operating between 115°–150°F, combining detergency with flash-rust protection. KMS-310 has a hardier detergency potency for moderate to heavy-duty hydrocarbon soils and particulates.

- KF-123 and KF-124 add extended flash-rust resistance, useful where parts undergo short-term handling before further processing.

- As no to low foam solutions – DA-23C and DA-24C are specifically Spray system compatible solutions.

Immersion Washers:

Immersion parts washer fluid systems submerge parts for full coverage cleaning, making them suitable for complex parts and heavy soil loads. Depending on the formulation, ZERUST® immersion-compatible parts washer fluids are engineered to work effectively in heated tanks as well as at room temperature.

Best Choices: KF-121, KF-122, KF-123, KF-124, NW-10C, NW-12C

- KF-121 and KF-122 provide medium to heavy-duty cleaning for tough soils.

- KF-123 and KF-124 support medium-duty soil removal in immersion baths, maintaining stability in demanding shop environments, whilst offering extended flash-rust protection for additional handling time.

- NW-10C and NW-12C operate effectively between 77–140°F, reducing energy consumption while cleaning light to medium to heavy duty soils while offering extended flash-rust protection for additional handling time.

Rotary Basket Systems:

Rotary basket parts washer fluid systems combine immersion, spray, and agitation, making them highly effective for cleaning small or intricate parts in high volumes. These systems demand low-foam, durable parts washer fluid formulations that withstand continuous operation.

Best Choices: KF-121, KF-122, KF-123, KF-124, KMS-305AL, KMS-310AL, KMS-220

- KF-121 and KF-122 provide low-foam cleaning to medium to tough soils.

- KF-123 and KF-124 provide low-foam detergency for medium-duty soils, leaving behind a flash rust-resistant coating for additional handling time.

- KMS-305AL and KMS-310AL deliver consistent cleaning in elevated temperature ranges (115–150°F), specifically designed for aluminum.

- KMS-220 has a special edge for Rotary Basket systems; not only does it provide effective cleaning for light to medium duty soils, but also oil-splitting capabilities. These oil-splitting features allow for a longer bath part and cleaner parts.

Ultrasonic Washer System:

Immersion parts washer fluid systems fully submerge parts in the cleaning solution, ensuring complete coverage for complex shapes and hard-to-reach areas. Fluids used in immersion systems must maintain stability across a range of temperatures and soil loads, delivering strong detergency while protecting against flash rust and corrosion during and after cleaning.

Best Choices: NW-10C, NW-12C, KF-121, KF-122, KF-123, KF-124, KMS-310AL

- NW-10C provides light-duty cleaning at room temperature (77–140°F), reducing energy consumption, with high-foam properties that support ultrasonic agitation.

- NW-12C extends versatility, compatible with ferrous and non-ferrous metals, stable in hard water, and effective in ultrasonic tanks requiring broader substrate coverage.

- KF-121 and KF-122 are excellent for cleaning medium to heavy-duty soils where emulsification is needed to help clean the parts.

- KF-123 and KF-124 can provide flash corrosion inhibition while tackling light and medium-duty soils in ultrasonic systems.

- KMS-310AL is designed to clean medium to tough soils from aluminum surfaces and has excellent emulsification ability.

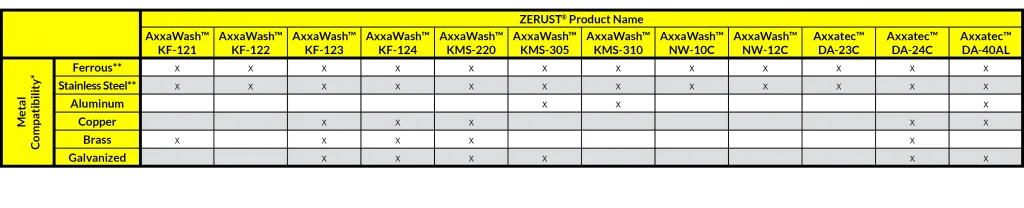

Metal Compatibility

Different metals require specific parts washer fluid properties to avoid etching, staining, or corrosion.

Stainless Steel

These fluids remove soils without staining or pitting stainless finishes, making them ideal for high-value precision parts in the parts washer system.

Best Choices: KF-121, KF-122, KF-123, KF-124, KMS-220, KMS-305AL, KMS-310AL, NW-10C, NW-12C

Aluminum

Compatible with sensitive aluminum surfaces, these products prevent etching and offer corrosion protection during or after cleaning in the parts washer fluid system.

Best Choices: KMS-310AL, KMS-305AL, DA-40AL

Copper & Brass

Gentle formulations prevent discoloration or tarnishing while effectively removing machining oils in the parts washer fluid system.

Best Choices: DA-24C, DA-40AL, KF-123, KF-124, KMS-220

Galvanized Steel

Specifically formulated to clean galvanized substrates without stripping or damaging the protective zinc coating in the parts washer fluid system.

Best Choice: KF-123, KF-124, KMS-220, DA-40AL, KMS-305AL

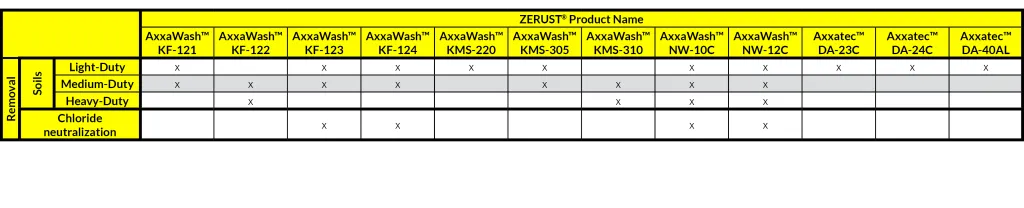

Soil Removal Performance

Selecting the right fluid also depends on the type and severity of soils present on the parts.

Light-Duty Soils (dust, light machining oils, residues)

These parts washer fluids remove light contaminants efficiently, with options like DA-23C, DA-24C, KMS-220, KMS-305AL and DA-40AL providing additional rust protection for storage.

Best Choices: DA-23C, DA-24C, KMS-220, KMS-305AL and DA-40AL

Medium-Duty Soils (heavier machining oils, shop grime, coolants)

Balanced detergency and corrosion inhibitors make these parts washer fluids ideal for typical industrial soils without over-aggressive cleaning.

Best Choices: KF-121, KF-123, KF-124, KMS-305AL

Heavy-Duty Soils (grease, burnt-on oils, carbonized deposits)

Engineered for immersion systems, KF-122, NW-10C, NW-12C, and KMS-310AL, blend high detergency, hard water tolerance and excellent emulsification.

Best Choice: KF-122, NW-10C, NW-12C, and KMS-310AL

Corrosion Protection

A key advantage of ZERUST® fluids is their built-in corrosion protection, ranging from immediate flash-rust prevention to extended protection for storage and shipping.

Flash-Rust Protection (during and immediately after cleaning)

These parts washer fluids contain corrosion inhibitors to protect ferrous parts during cleaning in the parts washer and short-term handling.

Best Choices: KF-123, KF-124, NW-10C, NW-12C

Up to 3 Months Corrosion Protection

Dual-function cleaners that also deliver multi-month protection, eliminating the need for an additional corrosion inhibitor step.

Best Choices: DA-23C, DA-24C, DA-40AL

Choosing the right parts washer fluid depends on your washer type, the materials you’re cleaning, and the level of protection you need after washing. ZERUST® solutions are engineered to deliver performance, safety, and sustainability—helping you keep operations efficient and compliant.