Who?

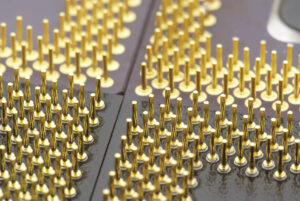

Global supplier of brake, chassis and drive components to the automotive industry

What?

Corrosion solutions providing clean, dry and corrosion free parts

Why?

Experiencing rust issues with components shipping within North America

How?

Switched from competitor’s open cell VCI Foam to custom sized ZERUST® ICT®570 VCI Foam sheets, eliminating corrosion