This guide explains the advantages and disadvantages of VCI Poly vs VCI Paper, helping you choose the right solution for your packaging and corrosion prevention needs.

The history behind VCI Poly vs VCI Paper

The earliest vapor corrosion inhibitor products appeared in the 1940s with the introduction of Dichan. This chemistry relied on dicyclohexylamine nitrite, which released corrosion-inhibiting vapor into the surrounding air. Manufacturers initially applied this chemistry to paper substrates.

However, these early VCI paper products had major limitations. The inhibitor diffused too quickly due to its high vapor pressure and often flaked off the paper surface. In addition, the paper retained moisture when placed directly against metal, which could accelerate corrosion instead of preventing it. Health concerns associated with early chemistries also drove the need for improvement.

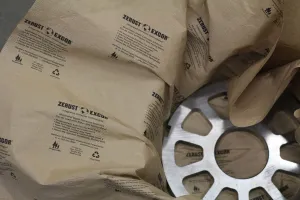

A major breakthrough came in 1979 when Northern Technologies International Corporation developed a safer VCI chemical system based on sodium nitrite and successfully impregnated it into plastic film. By the early 1980s, the same advanced technology was applied to paper products under the ZERUST® brand.

These innovations reshaped the conversation around VCI Poly vs VCI Paper and continue to influence packaging decisions today.

VCI Poly vs VCI Paper: Advantages of VCI Poly film

When evaluating VCI Poly vs VCI Paper, VCI poly film offers several performance advantages.

When evaluating VCI Poly vs VCI Paper, VCI poly film offers several performance advantages.

Moisture barrier performance

VCI poly film provides a significantly stronger moisture barrier than VCI paper. Poly film reduces water vapor transmission and helps prevent ambient humidity from entering the package. This added moisture control is critical for preventing corrosion during storage and shipment.

Ease of use and visibility

VCI poly packaging simplifies handling. Parts can be placed directly into VCI bags or crates lined with film, then sealed. Translucent film allows operators to identify contents quickly without opening the package.

Contamination protection

VCI poly bags protect metal parts from dust, debris, and airborne contaminants during storage and transit. Standard plastic bags may block dirt, but they do not provide corrosion-inhibiting vapor protection.

Shelf life and service life

VCI poly film typically offers long shelf life when stored in the original airtight packaging, often up to three years. When applied correctly, it provides long-term corrosion protection while keeping metal surfaces clean and dry.

Explore ZERUST® VCI Packaging Films

See VCI bags, films, and sheeting options designed to protect metal parts with reliable vapor corrosion inhibitor technology.

VCI Poly vs VCI Paper: Advantages of VCI Kraft paper

VCI Kraft paper also offers unique benefits when comparing VCI Poly vs VCI Paper, especially in certain packaging applications.

VCI Kraft paper also offers unique benefits when comparing VCI Poly vs VCI Paper, especially in certain packaging applications.

Fast vapor diffusion

VCI Kraft paper allows corrosion-inhibiting vapor to diffuse quickly, helping the chemistry reach metal surfaces faster than poly film in some applications.

Cost considerations

VCI Kraft paper typically has a lower material cost than VCI poly film, making it attractive for high-volume or short-term packaging needs.

Forming and wrapping parts

VCI paper conforms easily around complex shapes and individual components, making it useful for wrapping parts directly or stabilizing items inside a container.

Cushioning during shipment

When crumpled, VCI Kraft paper provides light cushioning that helps protect parts from movement and contact damage during shipping.

Discover ZERUST® VCI Kraft Paper Solutions

Learn how ZERUST® VCI Kraft paper delivers fast vapor diffusion, flexible wrapping, and reliable corrosion protection for metal parts.

Using VCI Poly & VCI Paper together for maximum protection

The good news is that VCI Poly vs VCI Paper is not an either-or decision. Many corrosion protection programs combine both materials to leverage their strengths.

For example, containers can be lined with a VCI poly gusset bag while individual components are wrapped in VCI paper for stabilization. VCI poly sheeting or VCI Kraft paper can also be used as an interleaving material between layers. This approach increases VCI saturation inside the package and ensures vapor reaches all internal spaces.

Choosing the right solution for your applications

Selecting between VCI Poly vs VCI Paper depends on factors such as moisture exposure, storage duration, shipping conditions, and part geometry. In many cases, a combined approach delivers the most reliable results.

ZERUST® helps manufacturers evaluate corrosion risks and implement effective, cost-efficient solutions. Our team conducts on-site assessments, including packaging audits, fluid audits, and data logger analysis, to identify improvement opportunities. The goal is to deliver the right products, processes, and procedures to achieve consistent corrosion protection.

Need help choosing between VCI Poly vs VCI Paper?

ZERUST® corrosion experts can evaluate your packaging process, environment, and storage conditions to recommend the most effective and cost-efficient corrosion protection solution.