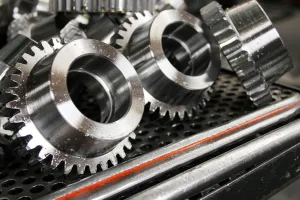

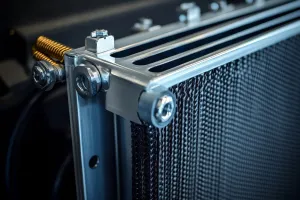

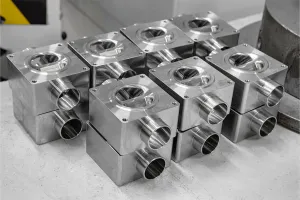

ZERUST® Parts Washer Fluid solutions effectively remove residual contaminants and hydrocarbon soils from the part’s surface, leaving it clean and contaminant-free, reducing flash rust and corrosion risk.

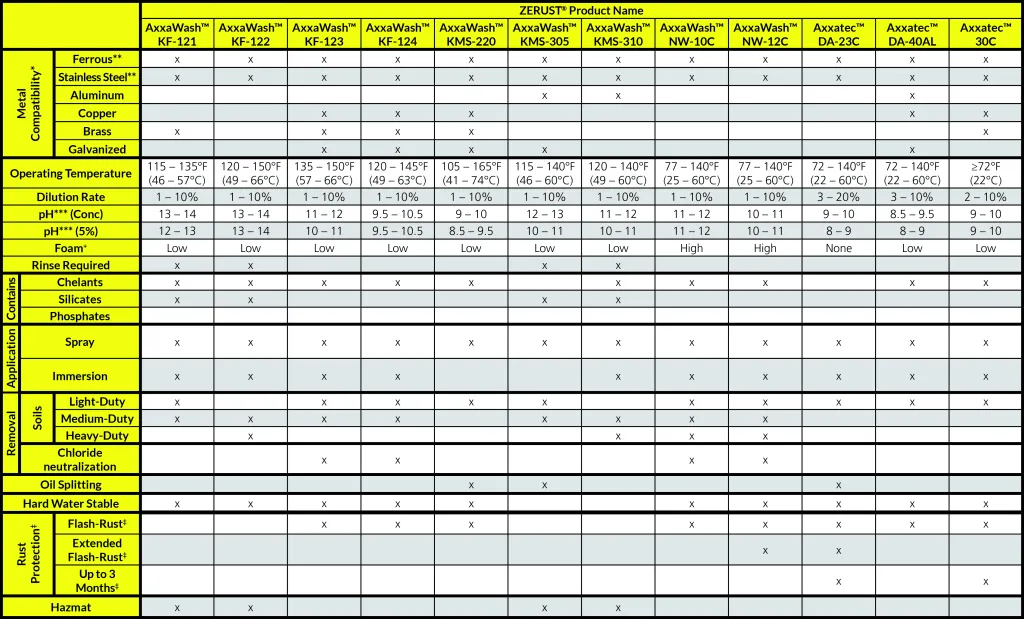

Formulated with advanced corrosion inhibitors, our parts washer fluid solutions are available in a range of chemistries to meet the specific needs of your metals, soils, application parameters and cleaning systems.