When evaluating VCI compared to desiccants for corrosion prevention, the key difference lies in how each technology works. Vapor Corrosion Inhibitor Technology (VCI) actively protects metal surfaces, while desiccants only passively manage moisture. Understanding this distinction helps determine which solution delivers reliable corrosion protection in real-world packaging, storage, and shipping environments.

How VCI Technology Actively Protects Metal

ZERUST® VCI technology provides active corrosion protection by releasing invisible, odorless, non-toxic vapor corrosion inhibitor (VCI) molecules into an enclosed space. For example, a sealed ZERUST® VCI bag continuously releases these molecules until the internal air space reaches saturation. Once released, the VCI molecules migrate throughout the enclosure and adsorb onto all exposed metal surfaces, including hard-to-reach areas such as internal cavities, threads, and crevices. This process forms a transparent, self-repairing molecular layer that passivates the metal surface and interrupts the

electrochemical reactions that cause rust and corrosion. Because this protection works at the molecular level, VCI compared to desiccants offers protection even when humidity fluctuates or when trace moisture remains inside the package.

How Desiccants Provide Passive Moisture Control

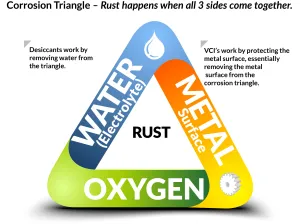

Desiccants provide passive corrosion protection by absorbing moisture from the surrounding air. Like a sponge, a desiccant reduces relative humidity inside a package, which can help slow corrosion by limiting electrolyte formation on metal surfaces.

Desiccants provide passive corrosion protection by absorbing moisture from the surrounding air. Like a sponge, a desiccant reduces relative humidity inside a package, which can help slow corrosion by limiting electrolyte formation on metal surfaces.

However, when VCI is compared to desiccants, an important limitation becomes clear. Desiccants have a finite moisture-holding capacity. Once they reach saturation, they stop working. In some cases, saturated desiccants can even release absorbed moisture back into the enclosure, increasing corrosion risk instead of reducing it.

Desiccants also do not protect metal surfaces directly. They only influence humidity levels and cannot stop corrosion if moisture, contaminants, or condensation already exist on the metal.

VCI Compared to Desiccants: Key Differences

When comparing VCI to desiccants side by side, several performance differences stand out:

- VCI actively protects metal surfaces, while desiccants only absorb moisture

- VCI molecules reach enclosed and hidden metal areas; desiccants cannot

- VCI protection remains effective during humidity fluctuations

- Desiccants lose effectiveness once saturated

- VCI does not require frequent replacement based on moisture load calculations

These differences explain why many manufacturers rely on VCI technology for long-term storage, overseas shipping, and complex assemblies.

Can VCI and Desiccants Be Used Together?

In some severe environments, such as long ocean shipments or extreme humidity conditions, VCI compared to desiccants does not have to be an either-or decision. ZERUST® confirms that desiccants can be used alongside VCI packaging when applied correctly.

In these cases, desiccants help manage bulk moisture inside the package, while VCI molecules provide active corrosion protection directly on metal surfaces. Proper placement and sizing remain critical to avoid sealing excessive moisture inside the package.

Want a deeper look at how desiccants and VCI technology can work together?

Explore real-world guidance and best practices in the ZERUST® blog article

Can You Use Desiccants with VCI?

Why VCI Is Often Preferred Over Desiccants

When VCI is compared to desiccants in real-world applications, VCI technology often delivers more consistent and reliable corrosion protection. VCI does not rely solely on humidity reduction. Instead, it directly passivates metal surfaces, even when environmental conditions change.

This makes VCI especially effective for:

- Export packaging

- Long-term storage

- Complex or multimetal assemblies

- Environments with temperature cycling and condensation risk

Looking for a deeper technical breakdown of corrosion protection methods?

The ZERUST® article VCIs vs. Desiccants: What’s the Difference?

explains how each technology works and where they perform best.

Choosing the Right Corrosion Protection Strategy

Selecting between VCI compared to desiccants depends on your environment, shipment duration, and corrosion risk. Desiccants may work for short-term moisture control in tightly controlled environments. However, for most industrial applications, VCI technology provides a higher level of corrosion protection with fewer variables to manage.

If you are unsure which solution best fits your application, ZERUST® technical specialists can help evaluate your packaging conditions and recommend the most effective corrosion protection system.