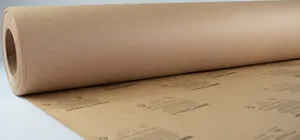

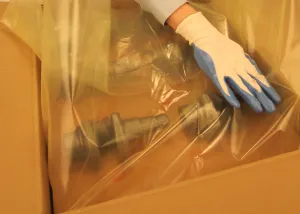

When customers first consider VCI, they commonly ask, can VCI paper or film absorb moisture from wet parts? The short answer is no. This is a common misconception about VCI moisture absorption from wet parts. Furthermore, VCI paper and VCI film do not absorb or remove water from metal surfaces. Instead, they release vapor corrosion inhibitors (VCI) that protect metal from rust when parts are properly prepared and enclosed.

Because of this, VCI materials protect metal from corrosion but do not dry parts or eliminate free moisture.

That said, VCI should NOT be relied on to compensate for:

- Standing water

- Water pooled in cavities

- Parts are packaged while still hot, which can cause condensation

Removing excess moisture improves protection, reliability, and consistency.

Best practices to manage VCI moisture absorption from wet parts

To reduce corrosion risk and get the most from VCI packaging, follow these best practices:

- Rinse parts to remove corrosive residues

- Allow parts to cool to ambient temperature

- Ensure parts are visibly dry before sealing

- Avoid trapping water in blind holes or crevices

- Combine VCI packaging with desiccants in high-humidity environments

These steps help ensure the VCI vapor can reach the metal surface and perform as intended.

Use VCI products correctly for maximum corrosion protection

Learn proven best practices for preparing parts and applying ZERUST® VCI products to ensure reliable corrosion protection in real-world conditions.

When additional corrosion protection is needed for wet parts

In some applications, VCI alone is not enough. For example, freshly washed parts, high-humidity storage, or export shipments may require supplemental protection.

In these cases, combining VCI packaging with rust preventative liquids, water-based inhibitors, or moisture control products can significantly reduce corrosion risk. Furthermore, a corrosion expert at ZERUST® can help evaluate the right approach based on your process and environment.

Need help protecting wet or freshly processed metal parts?

Every application is different. Contact ZERUST® to get expert guidance on VCI packaging, moisture control, and corrosion protection solutions tailored to your process.