What is VCI Film? VCI film is a specialized corrosion-inhibiting packaging material used to protect metal parts from rust and corrosion during storage, shipment, and work in progress. VCI stands for Volatile or Vapor Corrosion Inhibitors, which are chemical compounds that vaporize inside a sealed package and protect exposed metal surfaces.

ZERUST® applies VCI technology to polyethylene films by impregnating them with proprietary corrosion-inhibiting formulations. While the exact formulations vary by manufacturer, VCI films function similarly by releasing very low concentrations (typically in parts per ten-thousandth) of invisible corrosion-inhibiting vapors into the enclosed air space. These vapor molecules subsequently condense onto exposed metal surfaces, forming a molecular corrosion shield that can protect against rust and other forms of corrosion for many years. ZERUST® VCI packaging film is manufactured by Northern Technologies International Corporation (NTIC).

When VCI packaging is removed, the vapor corrosion inhibitors quickly dissipate, leaving metal parts clean, dry, and ready for immediate use without oils, greases, or post-treatment cleanup.

How Does VCI Film Work?

Key Benefits

VCI film offers several advantages compared to traditional rust preventative methods:

- Clean protection with no residue or surface coating

- Reduced labor by eliminating application and removal steps

- Protection for ferrous, non-ferrous, and multimetal assemblies

- Long service life, typically up to three years or longer in controlled conditions

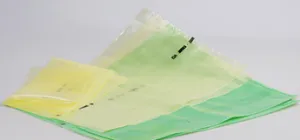

- Flexible packaging formats, including bags, sheets, tubing, and custom configurations

These benefits help manufacturers simplify packaging operations while maintaining reliable corrosion protection.

Common Applications for VCI Film

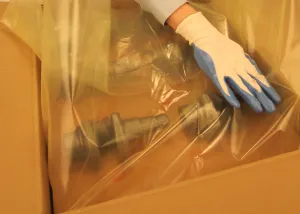

Vapor Corrosion Inhibitor film commonly used in applications where metal parts must remain corrosion-free throughout handling, storage, or transportation:

- Packaging machined components and metal stampings

- In process protection during manufacturing and assembly

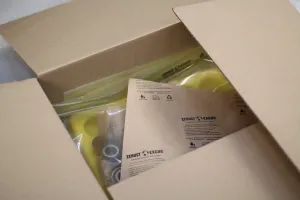

- Long-term storage of spare parts and equipment

- Domestic and overseas shipment of metal components

- Protection of finished assemblies and export packaging

Because vapor-phase protection covers all exposed surfaces, it’s is especially effective for parts with complex geometries.

What Affects Protection Duration?

What Happens When VCI Film Is Removed?

One of the primary advantages is that it leaves no residue on the metal surface. When the packaging is opened:

- VCI molecules rapidly evaporate from the metal

- No cleaning or degreasing is required

- Parts are immediately ready for assembly, processing, or end use

This makes it well-suited for just-in-time manufacturing and applications where cleanliness is critical.

Why Choose VCI Film Instead of Traditional Rust Preventatives?

Oils, greases, and coatings add labor and cleanup steps. VCI film offers clean, efficient corrosion protection that helps reduce handling, waste, and overall corrosion related costs.