VCI corrosion protection can remain effective for years when ZERUST® VCI products are selected, stored, and applied correctly. Protection duration depends on proper storage of unused materials, correct packaging methods, environmental exposure, and whether the enclosure remains sealed.

ZERUST® and EXCOR® VCI film and bags provide long-lasting corrosion protection for clean metal parts when used within three (3) years from receipt. Before use, store VCI materials in their original packaging, away from direct sunlight, and in conditions below 85°F (30°C) and

50 percent relative humidity.

Once parts are properly packaged, VCI molecules continuously protect exposed metal surfaces by forming a molecular corrosion-inhibiting layer inside the enclosed space.

How long does VCI corrosion protection remain effective after packaging?

When metal parts are clean, dry, and fully enclosed, VCI corrosion protection can remain effective throughout long-term storage and extended shipments. In many industrial applications, protection lasts several years as long as the packaging remains intact and sealed.

Opening the package or allowing excessive air exchange reduces VCI concentration inside the enclosure. Resealing with fresh VCI materials helps restore effective corrosion protection.

Factors that affect how long VCI corrosion protection remains effective

Several variables influence how long VCI corrosion protection remains effective in real-world applications.

Storage conditions before use

VCI films, bags, and papers should remain sealed in their original packaging until needed. Heat, humidity, and UV exposure can reduce the service life of unused VCI materials.

Cleanliness and surface preparation

VCI protects metal surfaces but does not neutralize existing corrosion or heavy contaminants. Oils, salts, fingerprints, and coolant residues can shorten protection duration if not removed before packaging.

Package integrity and sealing

VCI corrosion protection performs best in enclosed spaces. Poor seals, punctures, or frequent opening allow VCI vapors to escape and reduce long-term effectiveness.

Environmental exposure

High humidity, coastal environments, temperature cycling, and long ocean transits increase corrosion risk. These conditions often require supplemental protection methods.

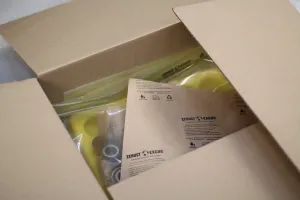

Using VCI diffusers with VCI packaging to extend protection life

VCI diffusers significantly extend corrosion protection in large enclosures, export crates, control panels, and equipment housings. When combined with VCI packaging, diffusers continuously release corrosion-inhibiting molecules to maintain effective vapor concentration over time.

This approach is especially useful when packaging cannot be perfectly sealed or when air volume is too large for film alone.

Using VCI diffusers with VCI packaging

Learn when and why combining VCI diffusers with VCI packaging provides more consistent corrosion protection in large enclosures and challenging environments.

How to use ZERUST® VCI products correctly for maximum effectiveness

Correct use directly impacts protection duration. To maximize effectiveness:

- Clean and dry all metal surfaces before packaging

- Fully enclose parts with the correct VCI material

- Minimize air exchange inside the package

- Avoid trapping free moisture or condensation

- Reseal packages immediately after inspection

Following these steps ensures VCI molecules can form and maintain a continuous protective layer on metal surfaces.

How to use ZERUST® VCI products correctly

Follow proven best practices for applying ZERUST® VCI products to maximize corrosion protection and ensure long-term performance.

ZERUST® VCI film additives and custom options for longer protection

ZERUST® VCI films can be engineered with additives tailored to specific metals, environments, and exposure durations. Custom options include enhanced humidity tolerance, multimetal protection, UV resistance, and increased vapor delivery rates.

These formulations help maintain corrosion protection longer in demanding applications such as export shipping, outdoor storage, and multimetal assemblies.

ZERUST® VCI film additives and custom options

Explore how ZERUST® VCI film additives and custom formulations enhance corrosion protection for specific metals, environments, and storage durations.

Best practices for VCI packaging storage before use

Unused VCI materials retain full performance when stored correctly. Follow these best practices:

- Keep VCI products sealed until use

- Store below 85°F (30°C) and 50 percent relative humidity

- Avoid direct sunlight and heat sources

- Rotate inventory to use older materials first

- Do not stack heavy loads that could damage the packaging

Proper storage ensures VCI products perform as intended when deployed.

Best practices for ZERUST® VCI packaging storage

Learn how proper storage conditions and material handling help preserve the performance of ZERUST® VCI packaging before it is put into service.

How long does VCI corrosion protection remain effective?

VCI corrosion protection remains effective for years when ZERUST® products are used within their recommended shelf life and applied correctly. Long-term performance depends on clean metal surfaces, sealed enclosures, controlled storage conditions, and selecting the right VCI system for the environment.

For complex applications, combining VCI packaging with diffusers, desiccants, or custom film formulations helps maintain consistent corrosion protection over extended periods.

Talk to a ZERUST® corrosion expert

Need help selecting the right VCI packaging, diffusers, or corrosion protection system for your application? ZERUST® experts can help you design a solution that delivers long-term protection.