As AI data centers exceed 100 kW per rack they producing heat loads rivaling dozens of household ovens in a single cabinet. No wonder cooling systems are working harder than ever. While everyone focuses on computational power, energy efficiency, and keeping servers cool, corrosion quietly erodes the very systems that keep AI workloads running. Here’s what every data center operator needs to know:

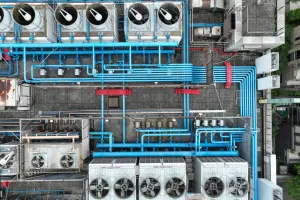

The Rising Thermal Challenge in AI Data Centers

AI Workloads are pushing data center cooling systems to unprecedented limits. Modern AI Facilities regularly pack 50kW, 100kW, or even more per rack. These are thermal loads that traditional cooling simply can’t handle. To handle these unprecedented thermal loads, operators are deploying advanced cooling architectures such as Direct-to-chip liquid cooling, rear-door heat exchangers, immersion tanks, and high performance CRAC (Computer Room Air conditioning) and CRAH (Air Handling) systems.

As cooling data centers becomes more complex and critical, one invisible threat accelerates across every component in the thermal management chain: corrosion. It may not seem as dramatic as a power outage or hardware failure, but corrosion silently erodes efficiency, shortens equipment lifespan, and system failure. Despite this, surprisingly few AI infrastructure discussions address it.

What Is Corrosion in Data Center Cooling Systems?

Corrosion is the gradual degradation of metal components through chemical reactions with their environment. In cooling data centers, this happens when metals like copper, aluminum, and steel are exposed to moisture, oxygen, coolant chemicals, and temperature fluctuations.

AI workloads make corrosion worse. This is because higher power densities mean:

- Higher operating temperatures accelerate chemical reactions

- Faster coolant flow erodes protective oxide layers

- Frequent thermal cycling that stresses metal joints and seals

- Mixed-metal systems increase galvanic corrosion risk

The result? Cooling infrastructure that degrades faster than ever before, often without visible warning signs until serious damage occurs.

How Corrosion Impacts Data Center Cooling Systems

AI-class cooling networks combine copper, aluminum, stainless steel, and brass components throughout their infrastructure. When these materials interact with humidity, oxygen, or degraded coolant fluids, several destructive processes begin:

- Pitting and fouling: Creates small holes and deposits in chillers, manifolds, and heat exchangers, drastically reducing thermal transfer efficiency

- Galvanic corrosion: Occurs when dissimilar metals (copper pipes connected to aluminum heat exchangers, for example) create electrochemical reactions that eat away at the more reactive metal

- Coil oxidation: Damages the internal coils of CRAC units, restricting airflow and reducing cooling capacity

- Coolant contamination: Corrosion byproducts circulate through the system, causing pressure drops, pump wear, and escalating energy consumption

Air-side economizer systems pull in outside air that may contain sulfur dioxide, chloride gases, and other atmospheric contaminants. These airborne pollutants accelerate corrosion in both IT hardware and HVAC components, particularly in coastal or industrial environments.¹

The Real Cost of Corrosion in Cooling Data Centers

One major U.S. data center discovered the hard way what unchecked corrosion costs. Glycol induced copper corrosion became so severe that operators had to replace the entire piping system with stainless steel, resulting in a seven-figure emergency repair that could have been prevented with proper corrosion management.²

The business impact of corrosion includes:

- Reduced equipment lifespan: Heat exchangers, coils, and manifolds exposed to fouling, corrosion, or thermal stress can experience premature degradation, leading to service lives significantly shorter than their intended design life.

- Leak and safety risks: In immersion-cooling environments, fluid leaks can damage nearby components and pose electrical or operational hazards if not promptly detected and contained.

- High cost of downtime: For data centers running AI or other critical workloads, unplanned outages can cost anywhere from $10,000 to over $40,000 per minute, depending on the scale and sensitivity of operations.

- Energy inefficiency: Fouled or corroded heat exchangers can lose 20–40% of their thermal performance, increasing energy use and operating costs.

- Reactive maintenance costs: Emergency repairs or replacements typically cost three to five times more than planned preventive maintenance, according to industry reliability studies.

Recent research confirms that chilled-water and liquid cooling systems can show measurable corrosion damage in as little as one to two years without proper treatment.³ What starts as microscopic pitting quickly escalates into leaks, equipment failure, and expensive emergency repairs.

Why Data Center Operators Are Prioritizing Corrosion Prevention

Forward-thinking facility managers now treat corrosion prevention as a Tier-1 maintenance discipline—not an afterthought.⁴ Here’s why:

- Corrosion damage is insidious. Unlike a failed pump or clogged filter, corrosion progresses invisibly inside pipes, coils, and closed-loop systems. By the time conductivity changes or leaks appear, significant damage has already occurred.

- AI cooling systems are particularly vulnerable. The combination of high heat loads, complex fluid dynamics, mixed-metal construction, and 24/7 operation creates ideal conditions for accelerated corrosion.

- Prevention costs far less than reaction. Implementing corrosion control during installation or routine maintenance is a fraction of the cost of emergency pipe replacement, coolant system flushing, or unplanned downtime.

The question isn’t whether your cooling infrastructure will experience corrosion, rather it is how soon and whether you’ll address it proactively or reactively.

ZERUST® Corrosion Protection Solutions for Data Center Cooling Systems

ZERUST® provides engineered corrosion prevention solutions designed specifically for the demanding environment of cooling data centers. Whether you operate traditional CRAC units, chilled-water loops, or cutting-edge liquid immersion systems, our products integrate seamlessly into your existing maintenance protocols without disrupting operations.

Our comprehensive portfolio addresses corrosion at every point in your cooling infrastructure—during active operation and critical idle periods.

For Active Cooling Systems

| Product | Application | Key Benefit |

|---|---|---|

| Axxatec™ HST-M100 | Glycol and chilled-water loops | Stabilizes pH, prevents internal rust and pitting in closed-loop systems. |

| VCI Diffusers & Capsules | CRAC cabinets and control boxes | Emits protective vapor layer without impacting airflow or equipment operation. Non-Residue & Electronic safe. |

| Axxanol™ 718-ESS Spray | Coils, fittings, and electronics | Forms a thin, non-conductive film safe for use on live electrical systems. |

For Idle & Backup Systems

| Product | Application | Key Benefit |

|---|---|---|

| VCI Films & Packaging | Storage or shipment of metal components | Prevents oxidation during logistics and spare parts inventory. |

| VCI Diffusers for Manifolds & Pumps | Idle or standby equipment | Protects sealed systems during. maintenance periods or seasonal lay-up |

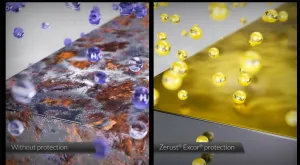

How VCI Technology Works

All ZERUST® products leverage vapor corrosion inhibitor (VCI) technology—a proven approach that creates an invisible molecular barrier on metal surfaces. When applied to data center cooling systems, VCI molecules:

-

- Vaporize and disperse throughout enclosed spaces or fluid systems

- Settle on all exposed metal surfaces

- Form a protective monomolecular layer that neutralizes corrosive agents

- Self-replenish continuously, maintaining protection over time

The ZERUST® advantage: Unlike traditional preservation methods that require complete flushing before restart, ZERUST® VCI treatments remain compatible with normal cooling system operation. Simply power up your equipment—no draining, rinsing, or special procedures required. This means faster returns to service and zero product waste.

Protecting Idle Cooling Systems: The Overlooked Vulnerability

Many data centers run backup chillers and supplemental cooling towers that sit idle for months during cooler weather. While operators focus on protecting active systems, these standby components face serious corrosion risk that’s often underestimated.

Why Idle equipment corrodes faster:

- Residual moisture trapped in “drained” systems that aren’t completely dry

- Condensation from temperature and humidity fluctuations as seasons change

- Stagnant fluid in partially-filled loops where inhibitors have degraded

- Oxygen exposure in unsealed components accelerating oxidation

- Concentration cells forming in low-flow areas with standing water

The harsh reality: Idle equipment can suffer more corrosion damage during three months of seasonal layup than during a full year of active, treated operation. When cooling demand returns and you fire up that backup chiller, hidden corrosion may have already compromised seals, weakened pipe walls, or contaminated the system.

ZERUST® Solutions for Seasonal Layup and Backup Systems

Wet Layup (Above Freezing Conditions):

Deploy Axxatec™ HST-M100 Corrosion-Inhibitor Additive in systems kept filled during idle periods. The formulation provides robust protection whether circulating or stagnant, and requires no removal before restart. Simply bring the system back online when needed.

Dry Layup (Freezing Risk or Drained Systems):

Install VCI Vapor Capsules inside drained chillers, cooling towers, manifolds, and pump housings. These diffusers release vapor-phase corrosion inhibitors that diffuse throughout void spaces, forming a protective molecular layer on all metal surfaces. As long as the system remains closed, protection continues—for weeks or months.

Control Components:

Control Components:

Place VCI Capsules in electrical control boxes and pump housings to protect sensitive components from humidity and corrosion during extended idle periods.

The Operational Advantage:

When temperatures climb and cooling demand returns, your backup systems restart immediately—no special preparation, no hidden damage, no surprises. You maintain your full cooling capacity exactly when you need it most.

Warning Signs: When to Check for Corrosion

Don’t wait for a leak or system failure. Watch for these early indicators of corrosion in your data center cooling systems:

- Increased energy consumption without corresponding load changes

- Discolored coolant or visible particles in fluid samples

- Rising differential pressure across heat exchangers

- Unusual metallic taste or smell in coolant fluids

- White, green, or blue deposits on pipe connections or fittings

If you notice any of these signs, immediate assessment and treatment can prevent minor issues from becoming expensive failures.

Implementing a Corrosion Prevention Program

Protecting your cooling infrastructure doesn’t require a complete system overhaul. A phased approach works for most facilities:

First Phase: Assessment – Week 1-2

- Inspect existing cooling systems for visible corrosion

- Test coolant chemistry and contamination levels

- Identify mixed-metal connections and high-risk areas

Second Phase: Treatment – Week 3-4

- Install VCI diffusers in CRAC units and control cabinets

- Add Axxatec™ HST-M100 inhibitor to chilled-water loops

- Apply protective coatings to exposed components

Third Phase Monitoring – Ongoing

- Quarterly coolant testing and pH monitoring

- Annual visual inspections of critical components

- Preventive VCI replacement on manufacturer schedules

ZERUST® technical team can help you design a customized program based on your specific cooling architecture, climate conditions, and operational requirements.

The Future of Data Center Cooling Systems: Proactive Corrosion Control

As AI power density continues to climb, corrosion control is no longer maintenance—it’s design engineering. Facilities that integrate proactive corrosion management from day one gain measurable advantages: higher uptime, lower operating costs, and extended system life.

As AI power density continues to climb, corrosion control is no longer maintenance—it’s design engineering. Facilities that integrate proactive corrosion management from day one gain measurable advantages: higher uptime, lower operating costs, and extended system life.

Don’t wait for corrosion to compromise your data center cooling systems. The damage is happening right now—invisibly, continuously, and expensively. So, whether you’re a facilities manager, MEP engineer, water treatment provider, or colocation operator, ZERUST® provides the tools and expertise you need to eliminate corrosion risks across your cooling infrastructure.

Contact ZERUST® today for a customized corrosion-prevention assessment. Our team will evaluate your specific cooling systems—including backup and idle equipment—identify vulnerabilities, and design a cost-effective protection program tailored to your facility.

References

- Shah, J. M., Gaynes, M. A., & Crawford, J. H. (2017). Qualitative Study of Cumulative Corrosion Damage of IT Equipment in a Data Center Utilizing Air-Side Economizer Operating in Recommended and Expanded ASHRAE Envelope. Journal of Electronic Packaging, 139(2), 020903.

- Data Cooling Center Stainless Steel Case Study. (2023). CSI Designs. Retrieved from https://www.csidesigns.com

- Corrosion Protection Reduces the Risk of Failure in Data Centre Cooling. (2021). Thermal Control Magazine. Retrieved from https://www.thermalcontrolmagazine.com

- Corrosion: A Clear and Present Danger. (2021). Data Centre Magazine. Retrieved from https://datacentremagazine.com