What is Hydrostatic Testing

What is Hydrostatic Testing

Hydrostatic testing is a technique used to verify the durability of pressure vessels, pipes, and other equipment, essential for detecting leaks and ensuring the structural integrity of these components. By filling items with water and pressurizing them, industries can ensure these assets will endure operational stresses.

Purpose and Applications of a Hydrostatic Test

Industries utilize a hydrostatic test to maintain compliance and ensure equipment reliability in sectors such as:

Industries utilize a hydrostatic test to maintain compliance and ensure equipment reliability in sectors such as:

- Gas and Oil Pipelines: Prevents leaks by verifying containment integrity.

- Chemical Processing Equipment: Confirms equipment can handle corrosive substances and high pressures.

- Transport Vessels: Ensures safe transport by verifying container integrity.

Compliance with regulatory standards, such as those from the Department of Transportation (DOT), is paramount, especially when dealing with pressure vessels and piping under high stress.

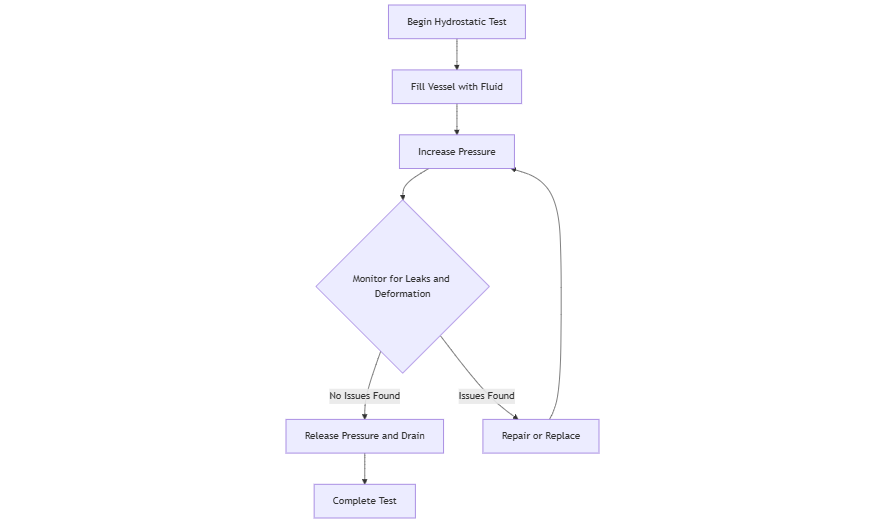

How Hydrostatic Testing Works: A Step-by-Step Guide

The hydrostatic testing process includes four critical stages:

- Filling the Vessel: Water or another suitable fluid fills the vessel.

- Pressurizing the Vessel: Pressure is increased to a specified level, often above standard operating pressure.

- Monitoring and Inspection: Observations are made for leaks or pressure drops.

- Pressure Release and Draining: After testing, pressure is carefully released, and the vessel is drained.

These steps help detect potential weaknesses, ensuring safe operation under normal conditions.

Types of Hydrostatic Testing

There are two main categories of hydrostatic testing:

- Type I (Initial Test): Conducted post-manufacturing to verify the entire vessel’s durability.

- Type II (Component Testing): Performed on specific parts within larger systems to confirm each component’s resilience.

Advantages of Hydrostatic Testing

The benefits of hydrostatic testing make it a preferred choice in various industries, offering:

- Leak Detection: Early identification of potential leaks.

- Cost Efficiency: Avoids costly repairs by validating integrity upfront.

- Regulatory Compliance: Ensures compliance with stringent standards.

- Increased Longevity: Extends equipment life by verifying robustness under pressure.

Testing provides a safeguard, protecting assets, environments, and personnel from the repercussions of equipment failure.

Protecting Against Corrosion in Hydrostatic Testing with ZERUST® Solutions

Given the high moisture environments involved, hydrostatic pressure tests can lead to rust and corrosion if unprotected. As a result, ZERUST® offers specialized Hydrostatic Testing Additives that counteract corrosion by treating the water used in the testing process, ensuring long-term integrity for pressure vessels and pipes.

ZERUST® AxxaVis™ HST-10

AxxaVis™ HST-10 is a water-soluble hydrostatic testing corrosion inhibitor that treats water by deactivating ionic contaminants responsible for rust and hard water deposits on ferrous metals during pipeline hydrostatic testing. Furthermore, this non-flammable, solvent-free solution can be safely discharged under environmental standards, and it’s compatible with ZERUST® Axxatec™ HST-M100 for applications involving copper or brass. AxxaVis™ HST-10 is an ideal solution for testing pipes, heat exchangers, and storage tanks, providing reliable corrosion protection.

AxxaVis™ HST-10 is a water-soluble hydrostatic testing corrosion inhibitor that treats water by deactivating ionic contaminants responsible for rust and hard water deposits on ferrous metals during pipeline hydrostatic testing. Furthermore, this non-flammable, solvent-free solution can be safely discharged under environmental standards, and it’s compatible with ZERUST® Axxatec™ HST-M100 for applications involving copper or brass. AxxaVis™ HST-10 is an ideal solution for testing pipes, heat exchangers, and storage tanks, providing reliable corrosion protection.

ZERUST® Axxatec™ HST-M100

Axxatec™ HST-M100 is a versatile, low-foam hydrotesting fluid additive suited for ferrous metals, copper, brass, and aluminum. It provides a corrosion-resistant finish that remains effective post-testing, ideal for protecting pipes and complex metal components. In addition, this additive deactivates ionic contaminants, ensuring compliance with global environmental regulations (RoHS, REACH, TSCA). Its application is straightforward and compatible with a variety of metals, making it a reliable choice across industries.

Axxatec™ HST-M100 is a versatile, low-foam hydrotesting fluid additive suited for ferrous metals, copper, brass, and aluminum. It provides a corrosion-resistant finish that remains effective post-testing, ideal for protecting pipes and complex metal components. In addition, this additive deactivates ionic contaminants, ensuring compliance with global environmental regulations (RoHS, REACH, TSCA). Its application is straightforward and compatible with a variety of metals, making it a reliable choice across industries.

ZERUST® Axxatec™ HST-20L

Specially formulated for ferrous metals, Axxatec™ HST-20L is a water treatment concentrate that mitigates corrosion risks by neutralizing harmful ions during hydro testing. Compliant with global environmental standards, Axxatec™ HST-20L is reusable in specific scenarios, providing a cost-effective solution for protecting vessels and pipes from rust. It’s easy to apply and flush, making it an environmentally friendly option that meets high safety standards.

Specially formulated for ferrous metals, Axxatec™ HST-20L is a water treatment concentrate that mitigates corrosion risks by neutralizing harmful ions during hydro testing. Compliant with global environmental standards, Axxatec™ HST-20L is reusable in specific scenarios, providing a cost-effective solution for protecting vessels and pipes from rust. It’s easy to apply and flush, making it an environmentally friendly option that meets high safety standards.

Diagram of Hydrostatic Testing Process

For clarity, here’s a simplified visualization of the process:

Why Choose ZERUST® Corrosion Solutions for Hydrostatic Testing?

ZERUST® hydrostatic corrosion solutions, such as AxxaVis™ HST-10, Axxatec™ HST-M100, and Axxatec™ HST-20L, offer comprehensive protection against rust, ensuring operational durability and regulatory compliance. These products extend the life of metal equipment, maintaining its integrity during and after testing and reducing environmental impact through reusable, eco-friendly formulations.

Ensuring Safety and Efficiency with Routine Testing

Regular hydrostatic testing combined with corrosion-prevention solutions like ZERUST® products ensures long-term safety and efficiency, preventing failures and minimizing maintenance costs. For businesses requiring high-pressure integrity in their operations, ZERUST® corrosion inhibitors provide robust, compliant solutions that support the highest safety and environmental standards.