Industry professionals widely perform hydrostatic testing as a standard method to verify the structural integrity and leak-tightness of pressure vessels. These include pipelines, plumbing systems, gas cylinders, boilers, above-ground storage tanks (ASTs), and fuel tanks. Testing these vessels is critical, especially when they are intended to transport or store gases. This is because failure under pressure can result in catastrophic explosions. The process involves filling the vessel or pipe system with a hydrostatic testing fluid, typically water, and pressurizing it to a specified level. A loss of pressure indicates the presence of a leak. In some cases, operators add a dye to the hydrostatic testing fluid to allow easier visual identification. To enhance corrosion protection during and after testing, technicians commonly include a hydrostatic testing additive in the fluid. This additive inhibits oxidation and prolongs the service life of the vessel.

Corrosion Risks in Hydrostatic Testing

Engineers and fabricators most commonly construct these pressure vessels from carbon steel alloys. These are generally prone to electrochemical corrosion during hydrostatic pressure tests. They are also prone during transport and/or storage if not effectively dried and/or protected using supplemental corrosion inhibitors or inert gas purging. The hydrostatic testing fluid used supplies the electrolyte required for the electrochemical corrosion cell. The quality of the hydrostatic testing fluid varies from high-quality deionized water to highly corrosive sea or brackish water. The type of hydrostatic testing fluid used directly influences the rate at which electrochemical corrosion initiates and propagates. Technicians add chemical additives to the hydrostatic testing fluid to mitigate this risk. These include contact and/or vapor corrosion inhibitors (VCI), oxygen scavengers, or a combination thereof. The inclusion of an effective hydrostatic testing additive is crucial for providing effective corrosion solutions during hydrostatic testing.

Managing Hydrostatic Testing Fluid and Environmental Compliance

When managing hydrostatic testing fluid, teams should implement pollution prevention and control measures. They can accomplish this by:

- Using the same hydro-test water for multiple tests to conserve water and minimize discharges of potentially contaminated effluent;

- Reducing the concentration of corrosion inhibiting or other chemicals by using high-quality water, such as deionized or reverse osmosis water;

- Selecting the least hazardous alternative with regard to toxicity, operator safety, biodegradability, and bioaccumulation potential;

- Dosing according to local regulatory requirements and manufacturer recommendations.

- Suppose discharge of hydro-test waters to the sea, surface water, or soil is the only feasible alternative for disposal. In that case, the project team should prepare a hydrostatic testing fluid disposal plan that considers the location and rate of discharge, chemical use (if any), dispersion, environmental risk, and required monitoring.

The Role of Oxygen and Water in Corrosion

Rust forms only when both oxygen and water are present. Even over several weeks, ferrous metals immersed in deoxygenated hydrostatic testing fluid (water) will not rust. Mechanical deaeration and chemical deoxygenation, i.e., the use of oxygen scavengers, effectively counters corrosion while the treated hydrostatic testing fluid is in contact with the metal substrate.

Mechanical deaerators work by heating the hydrostatic testing fluid and venting the gases. This operation reduces oxygen in the makeup fluid by more than 99%, leaving oxygen concentrations measured in the parts-per-billion range. However, at feedwater and boiler water temperatures, for example, even this trace amount of oxygen can create severe corrosion.

Therefore, technicians must chemically remove the last traces of oxygen from the hydrostatic testing fluid by dosing it with oxygen scavengers, typically in parts-per-million concentrations.

Proper mechanical deaeration is necessary for a well-run, cost-effective water treatment program. However, mechanical deaeration is costly and may not eliminate the need for a hydrostatic testing additive in certain testing environments.

Limitations of Deaeration Methods

Deaeration or deoxygenation methods have key limitations in corrosion control because they allow flash corrosion to spontaneously initiate when technicians empty the treated hydrostatic testing fluid from the vessels and expose them to atmospheric oxygen. When oxygen reaches a damp metal substrate, it accelerates the corrosion process, especially in areas with the lowest oxygen concentration.

If the area of the hydrostatic testing fluid adjacent to the metal shows low metal ion concentration, the region will turn anodic to the rest of the metal surface. Consequently, these areas will corrode quickly to boost the local concentration of ions.

Another often overlooked corrosion risk associated with using oxygen scavengers is their incompatibility with biocides. This is a significant problem in the oil and gas industry. For example, engineers often need to decide whether to prioritize microbial-induced corrosion control over electrochemical corrosion control or vice versa. In such cases, the use of a compatible hydrostatic testing additive becomes increasingly important.

Why Hydrostatic Testing Additives Offer a Better Alternative

Many fabricators favor the use of contact corrosion inhibitors and hydrostatic testing additives over deaeration or deoxygenation methods because these alternatives offer several distinct advantages. The chemistries used as contact corrosion inhibitors are typically organic or inorganic and range widely in terms of safety, efficacy, and toxicity. Using a highly effective, non-toxic, safe, and environmentally compliant hydrostatic testing additive is highly desirable, especially considering the large volumes of hydrostatic testing fluid used during the testing of large vessels such as boilers or pipelines. The right hydrostatic testing additive can simplify operations, enhance corrosion protection, and significantly reduce the environmental impact of fluid disposal.

170,000 liter boiler |

|

Disposal Considerations for Treated Hydrostatic Testing Fluid

At some point, technicians will need to dispose of the treated hydrostatic testing fluid. The chemical composition of the fluid will determine its disposal method. Waste treating it onsite or hauling it away for offsite waste treatment is not desirable and can be very expensive. What if operators could safely discharge the hydrostatic testing fluid to a municipal sewer, broadcast it over soil to suppress dust at construction sites, or even use it to water plants or crops, without harming the environment, animals, or humans? Selecting a hydrostatic testing additive that is non-toxic, biodegradable, and environmentally compliant can make such sustainable disposal options feasible and cost-effective.

The AxxaVis™ HST-10 Advantage

ZERUST® AxxaVis™ HST-10 is an effective, safe, non-toxic, and environmentally compliant hydrostatic testing corrosion inhibitor additive made from food-grade additives. Technicians determine use concentrations based on the water hardness and chloride content of the hydrostatic testing fluid. AxxaVis™ HST-10 offers excellent contact corrosion inhibition to all ferrous metals during pipeline hydrostatic testing operations. Additionally, it provides superior flash corrosion inhibition following the draining of the hydrostatic testing fluid and drying of the vessel interior surfaces.

Visual Case Studies and Performance Examples

Steel drum interior: One (1) year after being treated with a 0.5% solution of AxxaVis™ HST-10 |

1010 steel panels immersed for 7 months in 60 ppm chloride water. Left panel: with 0.5% HST-10; Right panel: control. |

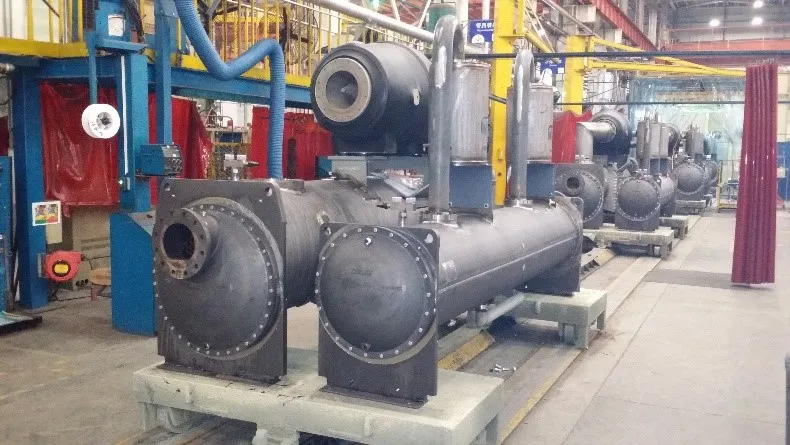

A large OEM suffered severe hydrostatic corrosion problems with their units due to their incumbent hydrostatic test operation. The photos below show the corroded header plate inside a typical unit immediately after draining the untreated hydrostatic testing fluid.

|

|

| Immediately after hydrostatic testing – Advanced corrosion of the header plate | |

To resolve this issue, the OEM introduced the AxxaVis™ HST-10 hydrostatic testing additive into their testing protocol and treated the hydrostatic testing fluid accordingly. The following photo shows a test unit one (1) week after hydrostatic testing with the additive in place.

A manufacturer of heat recovery steam generator harp assemblies also encountered corrosion of internal pipe surfaces during and after hydrostatic testing due to the corrosive nature of their untreated hydrostatic testing fluid. After adding 1% AxxaVis™ HST-10 hydrostatic testing additive to the fluid, the manufacturer eliminated the corrosion issue.

Without HST-10: Note the brown color of the water |

With HST-10: Hydro-test water remains water white |

Environmentally Safe Disposal

As determined by an independent 3rd party laboratory soil-spike test, it is possible to broadcast and distribute a used, clean solution of AxxaVis™ HST-10 hydrostatic testing additive, free of oils and soluble contaminants, over the soil. Additionally, discarding used, clean hydrostatic testing fluid treated with HST-10 into municipal drains is also an option. However, in both cases, companies must consult local authorities, who hold jurisdiction over handling waste streams, before discharging any hydrostatic testing fluid containing a hydrostatic testing additive.

Conclusion:

Teams should implement pollution prevention and control measures when managing hydrostatic testing fluid. AxxaVis™ HST-10 offers the following advantages:

- Using the same hydro-test water for multiple tests to conserve water and minimize discharges of potentially contaminated effluent;

- Teams can easily analyze and replenish the AxxaVis™ HST-10 solution for extended use

- Reducing the concentration of corrosion inhibiting or other chemicals by using high-quality water, such as deionized or reverse osmosis water;

- It is highly recommended to use high-quality water for hydrostatic testing, as this allows for lower concentrations of corrosion inhibitors. However, ZERUST® designed AxxaVis™ HST-10 to remain effective even when used with lower quality water, such as potable city water or water with high hardness and chlorides. Therefore, water quality dictates the required use concentration.

- Selecting the least hazardous alternative with regard to toxicity, operator safety, biodegradability, and bioaccumulation potential;

- ZERUST® formulates AxxaVis™ HST-10 using food-grade additives that are non-toxic, operator safe, 100% biodegradable, and have zero bioaccumulation potential.

- Dosing according to local regulatory requirements and manufacturer recommendations.

- Suppose the discharge of hydro-test waters to the sea, surface water, or the soil is the only feasible alternative for disposal. In that case, the project team should prepare a hydrostatic testing fluid disposal plan that considers the location and rate of discharge, chemical use (if any), dispersion, environmental risk, and required monitoring.

- “Clean” solutions of AxxaVis™ HST-10 can be discharged into municipal sewer systems or broadcast spread over the soil. It is, however, important to first consult with the local authorities. Regulations prohibit discharge into waterways or seawater.

Short-Term and Flash Corrosion Protection with AxxaVis™ HST-10 Hydrostatic Testing Additive

AxxaVis™ HST-10 offers effective and robust contact corrosion protection during short-term and extended hydrostatic testing programs, as well as effective flash corrosion inhibition of the wet surfaces following the draining of the hydro-test water. Furthermore, the treated surfaces retain short-term corrosion protection for up to 30 days or more, without additional corrosion inhibitors, when stored dry and exposed in controlled environments of ≤ 77°F (25°C) and ≤ 55% RH.