Knowing how to measure VCI bags correctly ensures proper fit, effective sealing, and reliable corrosion protection. Incorrect measurements can lead to loose packaging, poor vapor concentration, or wasted material. Follow the guidelines below to accurately measure flat bags, sleeves, sheets, and round-bottom VCI bags.

How to measure VCI bags correctly for flat bags

When learning how to measure VCI bags correctly for flat bags, always start with width and length.

- Width

- Measure from one outside edge of the bag to the other.

- If the bag uses slit seals, measure from inside seal to inside seal, or from inside seal to fold, depending on the bag construction.

- Length

- Measure from the open top of the bag down to the top of the bottom seal or fold. Do not include the seal thickness itself in the length measurement.

Accurate flat bag measurements ensure the part fits without excess air space that could reduce corrosion protection performance.

How to measure VCI bags correctly for sleeves

Understanding how to measure VCI bags correctly for sleeves is essential, as sleeves are open at both ends.

- Width

- Measure the sleeve from edge to edge when laid flat. This dimension determines the maximum part width the sleeve can accommodate.

- Length

- Measure from one cut edge to the other cut edge. Since sleeves have no bottom seal, the full cut length is usable.

Correct sleeve measurements help prevent overstretching or incomplete coverage of metal parts.

How to measure VCI bags correctly for sheets

Sheets follow the same measurement principles as sleeves.

To measure sheets correctly:

- Measure width from cut edge to cut edge

- Measure length from cut edge to cut edge

Using the correct sheet size ensures full surface coverage and proper vapor distribution when wrapping or layering parts.

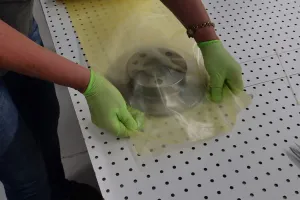

How to measure VCI bags correctly for round-bottom bags

Round bottom bags require extra attention when determining size.

- Width

- Measure across the flat width of the bag before it is expanded. This measurement represents the diameter capacity once the bag is opened.

- Length

- Measure from the open top of the bag to the top of the bottom seal, not including the sealed base.

Measuring round-bottom bags correctly ensures the bag expands evenly around cylindrical or irregular parts without stressing the seals.

Find the right VCI packaging solution from ZERUST®

ZERUST® offers a wide range of in-stock and custom VCI packaging films to meet your size, application, and corrosion protection requirements. Whether you need standard bag sizes or a custom solution, our experts can help you select the right VCI film for your needs.

Why measuring VCI bags correctly matters for corrosion protection

Knowing how to measure VCI bags correctly directly impacts corrosion protection performance. Properly sized bags:

- Maintain effective vapor concentration

- Allow secure sealing

- Reduce excess air volume

- Prevent part movement during transport or storage

Incorrect sizing can compromise the protective environment created by ZERUST® VCI packaging.

How to measure VCI bags correctly using a bag calculator

If you are unsure about sizing, you can simplify the process by using a bag calculator. These tools help translate part dimensions into recommended bag sizes, reducing guesswork and sizing errors.

Using a calculator alongside proper measurement techniques ensures the best possible fit and corrosion protection outcome.

Use the ZERUST® VCI bag calculator for accurate sizing

The ZERUST® VCI bag calculator helps you quickly determine the correct bag size based on your part dimensions. Using the calculator reduces sizing errors and helps ensure proper fit, sealing, and corrosion protection.

Common mistakes when learning how to measure VCI bags correctly

Avoid these common measurement errors:

- Measuring outside seals instead of inside seals on slit seal bags

- Including bottom seals in length measurements

- Measuring bags while folded or wrinkled

- Selecting oversized bags that dilute the vapor concentration

Careful measuring improves both packaging efficiency and corrosion protection reliability.

How ZERUST® can help you select the right solution

If you still have questions about how to measure VCI bags correctly or select the right packaging for your application, ZERUST® can help. Our corrosion experts work directly with customers to review part geometry, handling requirements, storage conditions, and shipment duration to recommend the ideal VCI bag size and product type. Contact ZERUST®/EXCOR® to work with our technical team and ensure your corrosion protection solution is properly sized, sealed, and optimized for long-term performance.

Work with ZERUST® corrosion protection experts

Selecting the correct VCI bag size and packaging solution is critical to effective corrosion protection. ZERUST® experts can help you confirm measurements, evaluate your application, and recommend the ideal VCI packaging solution for your needs.