When customers ask “what color is VCI Film?”, they are often looking for more than appearance. Color can indicate brand identity, application type, inspection visibility, and even custom performance requirements.

What color is VCI Film from ZERUST®?

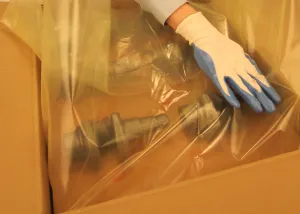

The trademark color for ZERUST® VCI film is yellow. This color is strongly associated with ZERUST® corrosion protection and allows for easy identification on the shop floor, in warehouses, and during shipping.

In addition to yellow, ZERUST® offers several stock VCI film colors, including:

- Blue

- Green

- Clear

- Gray

These options allow users to match internal handling preferences, customer requirements, or visual inspection needs while maintaining the same corrosion protection performance.

Explore ZERUST® VCI Film Options

ZERUST® offers VCI packaging films with stock and custom options to match your corrosion protection and process control needs.

Why does the color matter?

Understanding what color is VCI Film helps customers quickly distinguish specialized ZERUST® VCI packaging from standard clear polyethylene packaging. This visual differentiation is especially important in facilities that use both premium corrosion protection materials and conventional poly film.

Because VCI film is a premium product and carries a higher cost than plain poly packaging, color plays an important role in cost control. Distinctive colors such as yellow, blue, or green make it easy for operators to identify when VCI protection is required and avoid using it where corrosion protection is not needed.

Using colored VCI film helps customers:

- Prevent accidental use of higher-cost VCI packaging for noncritical applications

- Reserve corrosion protection materials for parts that truly require it

- Reduce unnecessary packaging costs and material waste

- Improve training, consistency, and process control on the shop floor

Clear poly packaging often looks similar to clear VCI film at a glance. Colored VCI film eliminates this confusion and reinforces proper use of corrosion protection throughout the operation.

When are VCI Film custom options required?

If stock colors do not meet your needs, ZERUST® can custom-produce VCI film in almost any color. This flexibility supports applications where branding, traceability, or process identification is critical.

Custom color options are commonly used to:

- Match OEM or customer brand guidelines

- Distinguish between metal types or protection durations

- Identify export, domestic, or long-term storage packaging

- Integrate visual controls into lean manufacturing systems

Custom colors can be combined with other performance enhancements such as UV stabilizers, antistatic additives, or specialty corrosion inhibitors.

Learn About ZERUST® VCI Film Custom Options

ZERUST® VCI film can be enhanced with custom colors, additives, and performance features to meet specific storage, shipping, and corrosion protection requirements.

Does the color of VCI Film affect corrosion protection?

The best answer depends on how the packaging will be used. When selecting a color, consider:

- Visibility requirements during handling and inspection

- Internal process control or color-coding systems

- Customer or regulatory preferences

- Indoor versus outdoor storage conditions

A ZERUST® corrosion expert can help match film color with performance requirements to ensure consistent, long-term protection.

Need Help Selecting the Right VCI Film?

ZERUST® corrosion experts can help you choose the right VCI formulation to protect your metal parts while controlling packaging costs.