VCI for wet parts requires careful consideration, as packaging metal components with surface moisture present can lead to a measurable amount of corrosion. When wet parts are packaged in ZERUST® VCI products, a limited amount of corrosion may occur initially. Specifically, this early-stage corrosion depends on how quickly corrosion-inhibiting molecules saturate the package enclosure, the effectiveness of the selected VCI system, the amount of moisture on the metal surface, and the pH or contamination level of the water.

Understanding how VCI performs in the presence of moisture helps manufacturers set realistic expectations and apply best practices to minimize corrosion risk.

How VCI Works on Wet Parts

When metal parts are sealed inside VCI packaging, corrosion-inhibiting molecules begin to volatilize and disperse throughout the enclosed air space. These molecules migrate toward metal surfaces and form a molecular protective layer that interferes with the electrochemical reactions responsible for

corrosion.

However, excess surface moisture can delay this process. Standing water, trapped droplets, or condensation can create localized corrosion sites before the VCI molecules fully establish protection. For this reason, VCI protects wet parts most effectively when moisture levels are controlled, rather than eliminated entirely.

Will Packaging Wet Parts in VCI Cause Corrosion?

Packaging wet metal parts in VCI may result in minor, short-term corrosion, especially during the initial sealing period. This corrosion typically stabilizes once the VCI environment becomes fully saturated.

Factors that influence corrosion risk include:

- The volume of moisture present on the part

- The cleanliness of the water, including salts or machining residues

- The enclosure size and seal integrity

- The corrosion-inhibiting strength of the selected VCI system

Reducing free water and contaminants before packaging significantly improves corrosion protection outcomes.

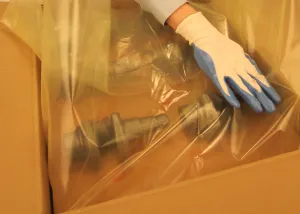

Best Practices for Packaging Wet Metal Parts in VCI

Following proven preparation steps greatly improves results when using VCI for wet parts:

- Remove standing water whenever possible

- Allow parts to reach ambient temperature before packaging

- Ensure surfaces are free of corrosive residues such as salts or chlorides

- Use properly sized, well-sealed VCI packaging

- Combine VCI film with complementary protection methods for severe environments

These practices help VCI molecules establish protection more quickly and uniformly.

Learn How to Use ZERUST® VCI Products Correctly

Proper application plays a critical role in corrosion prevention. Review best practices, common mistakes to avoid, and step-by-step guidance for using ZERUST® VCI products effectively.

What Happens If Condensation Forms Inside VCI Packaging?

Condensation can form when you seal warm parts and later expose them to cooler temperatures. This trapped moisture can temporarily increase corrosion risk before VCI protection fully develops.

To reduce condensation:

- Avoid packaging hot parts

- Stabilize temperatures before sealing

- Minimize empty air space inside the package

Proper temperature control improves the effectiveness of VCI corrosion protection for wet components.

Are There VCI Products Designed for Wet or Moist Parts?

Certain VCI systems are better suited for applications involving moisture, oils, or freshly washed parts. Furthermore, these systems may incorporate multimetal protection, higher inhibitor loading, or compatibility with complementary corrosion prevention methods.

Selecting the right solution depends on part geometry, metal type, exposure conditions, and shipment duration.

Need Help Selecting the Right VCI Solution?

Moisture levels, metal types, and environmental conditions all affect corrosion risk. Our corrosion specialists can help evaluate your application and recommend the right ZERUST® VCI system.

How Long Can Wet Parts Remain Protected in VCI Packaging?

Protection time varies based on moisture level, packaging integrity, and environmental conditions. Furthermore, when properly prepared and packaged, VCI for wet parts can provide corrosion protection during storage and shipment, even in humid or export environments. However, excessive water or contamination may reduce protection duration.

Common Mistakes to Avoid When Using VCI for Wet Parts

Avoiding these common issues helps reduce corrosion risk:

- Sealing standing water inside the package

- Packaging parts immediately after washing without surface preparation

- Ignoring temperature differences that cause condensation

- Using undersized or poorly sealed packaging

Correcting these issues improves consistency and long-term performance.

Get Technical Guidance for Wet Part Corrosion Protection

High humidity, saltwater exposure, multimetals, and long-term shipments require a properly engineered VCI system. Our corrosion specialists can review your application and help design the right solution for wet part conditions.