Subway systems worldwide rely heavily on electronic signaling components to ensure safe, reliable, and timely train operations. These components are exposed to harsh environmental conditions, such as moisture, temperature fluctuations, and airborne contaminants. For this reason, corrosion protection for electronic components in rail systems has become essential to maintaining performance and preventing costly failures.

The consequences of a single signaling failure can range from service delays to safety hazards and public scrutiny. To mitigate these risks, transit authorities must prioritize proactive corrosion protection as a critical aspect of infrastructure maintenance and system reliability.

The Impact of Corrosion on Electronic Components in Rail Systems

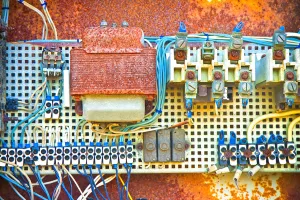

Electronic cards and control modules used in subway signaling systems are typically housed in enclosures designed to shield them from the environment. However, over time, even minimal ingress of moisture or corrosive agents like acid gases can lead to:

- Metal trace corrosion on PCBs

- Short circuits and intermittent failures

- Degradation of solder joints and connectors

- Failure of semiconductors and passive components

In dense urban transit environments like Singapore, London, or New York, these failures are not just technical issues; they are public reliability concerns and financial liabilities for transit authorities.

Why Corrosion Protection for Subway Electronics Is Critical

Unlike mechanical systems, electronic components do not provide early signs of degradation. Corrosion-related damage may be invisible until a failure occurs. The introduction of corrosion protection strategies allows railway operators to:

Unlike mechanical systems, electronic components do not provide early signs of degradation. Corrosion-related damage may be invisible until a failure occurs. The introduction of corrosion protection strategies allows railway operators to:

- Extend the lifespan of critical control electronics

- Reduce maintenance frequency and costs

- Minimize unplanned service disruptions

- Improve safety and operational continuity

This is particularly critical in communications-based train control (CBTC) systems and other modern signaling architectures where electronics form the backbone of automated operations.

ZERUST® Corrosion Protection Solutions for Electronic Components in Rail Systems

ZERUST® offers a comprehensive suite of corrosion prevention solutions specifically developed to protect electronic equipment in rail systems. These include:

ZERUST® offers a comprehensive suite of corrosion prevention solutions specifically developed to protect electronic equipment in rail systems. These include:

- VCI Films and Bags for shipping, storage, and work-in-progress protection

- VCI Emitters and Capsules for enclosed cabinets and control boxes

- Moisture control packets to reduce condensation risk

- Corrosion inhibitor sprays like Axxanol™ 718-ESS for live or static equipment

Each product line is designed to offer targeted protection for environments with high humidity, acid gas vapors, and restricted airflow.

Case Study: Mexico City Metro Implements ZERUST® VCI Vapor Capsules

One compelling example of successful corrosion protection implementation can be found in the Mexico City Metro, one of the world’s busiest underground transportation systems.

The Challenge

Electrical systems in the Metro operate up to 20 hours a day. Due to high usage, coupled with humidity and environmental contamination, the system experienced frequent false contacts and electrical terminal failures, resulting in costly maintenance cycles and compromised operational reliability.

The Solution

ZERUST® proposed the deployment of VCI Vapor Capsules, compact corrosion-inhibiting devices that release a safe vapor into enclosed spaces, such as electrical cabinets. As a result, this vapor forms a microscopic protective layer on metal surfaces, preventing corrosion without interfering with electrical function.

The Results

Over nearly a year of real-world testing within the Metro system, the following improvements were observed:

- Significant reduction in false electrical contacts

- Greater system stability under high humidity

- Decreased frequency of maintenance interventions

- Lower overall maintenance costs

The Outcome

Following the successful pilot, VCI Vapor Capsules were officially specified for use across all Mexico City Metro lines. Installation began with Line 1 and will be expanded to the entire system.

This case clearly illustrates the tangible benefits of proactive corrosion protection in high-demand, high-risk electronic environments.

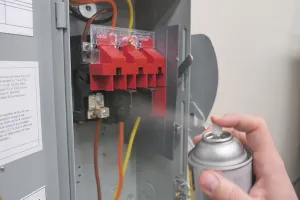

Axxanol™ 718-ESS: Protection for In-Service Electronics

Among ZERUST®’s most effective solutions is Axxanol™ 718-ESS, a multimetal corrosion inhibitor spray designed for active and stored electronic systems.

Product benefits:

- Forms a thin, water-displacing, non-conductive protective film

- Safe for use on energized or in-service electronics (when powered down)

- Ideal for PCBs, junction boxes, electric cabinets, and metallic parts

- Provides both corrosion protection and lubrication

- Compatible with ferrous and non-ferrous metals

This product is especially suited for transit systems seeking fast, effective, and clean application methods without the need for dismantling equipment.

Integrated Corrosion Management for Rail Systems

To effectively mitigate corrosion risks, transit authorities should implement a complete protection strategy, including:

- VCI packaging during storage and shipment

- VCI capsules or diffusers inside operational enclosures

- Periodic application of sprays like Axxanol™ 718-ESS during routine maintenance

- Moisture control and monitoring using desiccants and QR-tracked VCI replacements

- Ongoing training for maintenance personnel in corrosion prevention practices

As rail systems worldwide face increasing operational demands and aging infrastructure, corrosion protection for electronic components is more critical than ever. Furthermore, if left untreated, corrosion leads to system downtime, inflated maintenance budgets, and public safety risks.

ZERUST® corrosion protection solutions, including those featured in the successful Mexico City Metro case study, provide reliable, scalable answers to these challenges. Whether during operation, storage, or shipment, our VCI technologies help ensure that your electronics stay protected, your system stays reliable, and your passengers stay safe. Contact ZERUST®/EXCOR® today to discuss a corrosion protection strategy tailored to your specific application and operational environment.

Learn More About ZERUST® Electronic Rust Prevention

Protect your transit electronics with proven, field-tested solutions.